Penoplex insulation - technical characteristics, properties and areas of their application. Penoplex: choosing the optimal size of insulation How many square meters in a pack of penoplex

In winter, up to 50% of the heat escapes through the ceilings and walls of the house. To reduce heating costs, install thermal insulation. Installing insulation reduces heat loss, allowing you to save on utility bills. A popular material for insulating residential structures is penoplex of various thicknesses, in particular 50 mm.

Features: pros and cons

Thermal insulation material penoplex is made from polystyrene using the extrusion method. In production, polystyrene granules are melted at temperatures up to +1400 degrees. A foaming catalyst is introduced into the mixture, which enters into a chemical reaction to produce oxygen. The mass increases in volume, filling with gases.

During the manufacturing process, synthetic additives are introduced to improve the properties of the heat insulator. The addition of tetrabromoparaxylene ensures self-extinguishing in case of fire, other fillers and stabilizers protect against ultraviolet radiation and oxidation, and impart antistatic qualities to the finished product.

The expanded polystyrene composition under pressure enters the extruder chamber, where it is formed into blocks and cut into slabs 50 mm thick. The resulting slab contains more than 95% of gases enclosed in polystyrene cells no larger than 0.2 mm in size.

Due to the characteristics of the raw materials and fine-cell structure, extruded polystyrene foam exhibits the following technical characteristics:

- the thermal conductivity coefficient varies slightly depending on the humidity of the material from 0.030 to 0.032 W/m*K;

- vapor permeability is 0.007 Mg/m*h*Pa;

- water absorption does not exceed 0.5% of the total volume;

- the density of the insulation varies depending on the purpose from 25 to 38 kg/m³;

- compressive strength varies depending on the density of the product from 0.18 to 0.27 MPa, maximum bending – 0.4 MPa;

- fire resistance class G3 and G4 in accordance with GOST 30244, refers to normally and highly flammable materials with a smoke emission temperature of 450 degrees;

- flammability class B2 in accordance with GOST 30402, moderately flammable material;

- spread of flame over the surface in group RP1, does not spread fire;

- with high smoke-forming ability under group D3;

- material thickness 50 mm has an airborne noise insulation index of up to 41 dB;

- temperature conditions of use – from -50 to +75 degrees;

- biologically inert;

- does not collapse under the influence of building mortars, alkalis, freon, butane, ammonia, alcohol and water-based paints, animal and vegetable fats, organic and inorganic acids;

- is subject to destruction when gasoline, diesel, kerosene, tar, formaldehyde, diethyl alcohol, acetate solvent, formaldehyde, toluene, acetone, xylene, ether, come into contact with the surface, oil paint, epoxy resin;

- service life – up to 50 years.

- Resistance to mechanical damage. The higher the density, the stronger the product. The material breaks with force, does not crumble, and dents slightly. The combination of characteristics allows this material to be used to insulate both objects under construction and buildings in need of reconstruction and repair. The properties of the material determine the positive aspects when using penoplex with a thickness of 50 mm.

- The thickness of the insulating layer is small compared to other insulation materials. Thermal insulation of 50 mm of extruded polystyrene foam is equivalent to 80-90 mm of a layer of mineral wool insulation and 70 mm of polystyrene foam.

- Water-repellent qualities do not allow the growth of fungi and bacteria to be maintained, which meets sanitary and hygienic requirements, demonstrating the biological resistance of the heat insulator.

- Doesn't call chemical reaction in contact with alkaline and saline solutions, construction mixtures.

- High level of environmental safety. During production and operation they are not emitted harmful substances, which can negatively affect environment and people's health. You can work with insulation without personal protective equipment.

- Quick payback of the heat insulator due to reasonable cost and savings on coolants.

- The ability to self-extinguish, does not support or propagate combustion.

- Frost resistance down to -50 degrees allows you to withstand 90 cycles of temperature and humidity influences, which corresponds to a durability level of 50 years of operation.

- Unsuitable for living and breeding of ants and other insects.

- Light weight makes it easy to transport, store and install.

- Quick and easy installation due to dimensions and locking connections.

- Wide range of applications and versatility. Approved for use in residential, public, industrial, agricultural buildings and structures.

- The material is not resistant to fire and emits acrid smoke when smoldering. The outer side can be plastered so that there is no direct contact with the flame. This increases the flammability group to G1 - low-flammable substances.

Any building and thermal insulation material has negative points during operation. They must be taken into account during installation and reduce the risks of thermal insulation of structures. Among the disadvantages of penoplex, several characteristics can be identified.

- Chemical solvents can destroy the top layer of the material.

- A low level of vapor permeability leads to the formation of condensation on the insulating base. Therefore, it is necessary to insulate the walls outside the premises, leaving a ventilation gap.

- Becomes brittle with prolonged exposure to ultraviolet radiation. To avoid harmful consequences, penoplex must be protected from sunlight by external finishing. This can be plaster, a ventilated or wet facade system.

- Low adhesion to various surfaces requires fixation with façade dowels or specialized adhesives.

- The material can be damaged by rodents. To protect the heat insulator, which is open to mice, use a metal mesh with 5 mm cells.

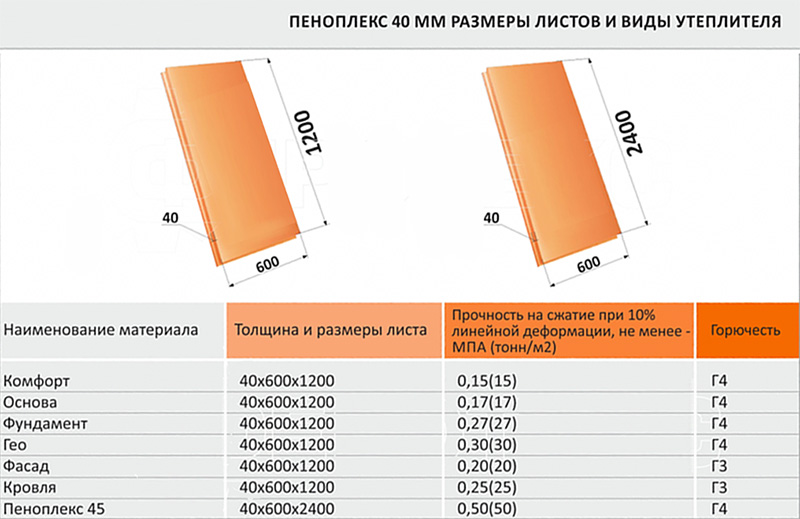

Sheet sizes

Penoplex dimensions are standardized and convenient for installation. The sheet width is 60 cm, length - 120 cm. The insulation thickness of 50 mm allows you to provide the required level of thermal insulation in a temperate climate.

The number of squares required for insulation is calculated in advance, taking into account the area of the structure.

Penoplex is supplied in polyethylene shrink film. The number of pieces in one pack depends on the type of material. The package of the universal heat insulator contains 7 sheets with a volume of 0.23 m3, allowing you to cover an area of 4.85 m2. A pack of penoplex for walls contains 8 pieces with a volume of 0.28 m3 and an area of 5.55 m2. The weight of the package varies from 8.2 to 9.5 kg and depends on the density of the insulation.

Scope of application

Insulation in the house must be comprehensive in order to achieve an effective reduction in heat loss. Since up to 35% of heat escapes through the walls of a house, and up to 25% through the roof, the thermal insulation of wall and attic structures must be carried out with suitable heat insulators. Also, up to 15% of heat is lost through the floor, so insulating the base and foundation will not only reduce heat loss, but also protect against destruction under the influence of ground movement and soil erosion groundwater.

Penoplex 50 mm thick is used in individual and professional field construction.

Types of insulation are divided according to the scope of application in thermal insulation work. In low-rise buildings and private apartments, several series of penoplex are used.

- “Comfort” with a density of 26 kg/m3. Designed for insulation of cottages, dachas, bathhouses and private houses. “Comfort” slabs are used to insulate walls, plinths, floors, ceilings, attics, and roofs. In the apartment it is used to expand the area and get rid of dampness on loggias and balconies. In suburban construction it is suitable for creating gardening areas. Thermal insulation of the soil under garden paths and garage areas will avoid deformation of the finishing coating. These are universal slabs with a strength of 15 t/m2; one cube contains 20 m2 of insulation.

- "Foundation", whose density is 30 kg/m3. It is used in private housing construction in loaded structures - traditional, strip and shallow foundations, ground floors, blind areas, basements. The slabs can withstand a load of 27 tons per square meter. Protect the soil from freezing and inflow groundwater. Suitable for thermal insulation garden paths, drains, drainage channels, septic tanks and pipelines.

- "Wall" average density 26 kg/m3. Installed on internal and external walls, partitions. In terms of thermal conductivity, 50 mm insulation replaces a 930 mm thick wall made of bricks. One sheet covers an area of 0.7 m2, increasing the speed of installation. Grooves on the edges remove cold bridges running deep into the surface of the walls and shift the dew point. Ideal for use on facades with further decorative finishing. The milled rough surface of the slabs helps to increase adhesion to plaster and adhesive mixtures.

In professional construction, the size of the slabs can vary; they are cut into lengths of 120 and 240 cm. The following brands of penoplex slabs are used for thermal insulation of multi-apartment residential buildings, industrial, commercial, public facilities, sports and industrial facilities.

- "45" characterized by a density of 45 kg/m3, increased strength, and can withstand a load of 50 t/m2. Designed for use in road construction - laying roads and railways, reconstructing city streets, constructing embankments. Thermal insulation of roads helps reduce the consumption of building materials, the cost of repairing the roadway, and increases its service life. The use of Penoplex 45 as thermal insulating layers in the reconstruction and expansion of the airfield runway makes it possible to reduce the deformation of the coating on heaving soils.

- "Geo" designed for a load of 30 t/m2. A density of 30 kg/m3 allows you to insulate the foundation, basement, floors and used roofs. Penoplex protects and insulates the monolithic foundation of a multi-story structure. It is also included in the structure of a shallow slab foundation with the laying of internal utilities. Used for laying floors on the ground in residential and commercial premises, V industrial refrigerators, in ice arenas and skating rinks, for the foundation of fountains and the construction of pool bowls.

- "Roof" with a density of 30 kg/m3 designed for thermal insulation of any roofing structures starting from pitched roof, ending with a flat roof. Strength of 25 t/m2 allows installation on inverted roofs. These roofs can be used for parking or green recreation area. Also, for the insulation of flat roofs, the Uklon brand of penoplex has been developed, which allows for water drainage. The slabs are created with a slope from 1.7% to 3.5%.

- "The basis" medium strength and density 24 kg/m3 is an analogue of the “Comfort” series, designed for universal insulation of any structures in civil and industrial construction. Used for external wall insulation in multi-storey buildings, internal insulation basements, filling expansion joints, creating door and window lintels, for constructing multi-layer walls. Layered masonry consists of an internal load-bearing wall, a foam layer and an external brick or tile finish. This type of masonry reduces the thickness of the walls by 3 times compared to the requirements of building regulations for a wall made of a homogeneous material.

- "Facade" with a density of 28 kg/m3 it is used for thermal insulation of walls, partitions and facades, including first and basement floors. The milled surface of the slabs simplifies and reduces plastering work. finishing facade.

A guarantee of the effectiveness of thermal insulation is compliance with all stages and rules of installation work.

- Before installing penoplex, you need to prepare the surface on which the material will be laid. A non-uniform surface with cracks and dents must be sealed with a plaster mixture. If there is debris, loose elements and remnants of old finishing, then the interfering parts are removed.

- If traces of mold and moss are detected, the affected area is cleaned and treated with an antiseptic fungicidal mixture. To improve adhesion to the adhesive composition, treat the surface with a primer.

- Penoplex is a rigid, inflexible thermoplastic that is attached to smooth surfaces. Therefore, the level of evenness is measured. If the difference exceeds more than 2 cm, then leveling will be required. The technology for installing heat insulators differs slightly depending on the surface design - for the roof, walls or floor.

- Installation of thermal insulation can be carried out at any time of the year, but it is more comfortable if the temperature is above +5 degrees. To fix the slabs, special adhesives based on cement, bitumen, polyurethane or polymers are used. Facade mushroom-shaped dowels with a polymer rod are used as additional fastenings.

- Installation on walls is carried out using the horizontal method of placing slabs. Before installing penoplex you need to place starting bar so that the insulation is in the same plane and the rows do not move. The bottom row of insulation will rest on the bottom bar. The heat insulator is attached to glue in a checkerboard pattern with the grooves aligned. The adhesive composition can be applied in strips of 30 cm or in a continuous layer. Be sure to coat the connecting edges of the panels with glue.

- Next, holes are drilled to a depth of 8 cm. For one sheet of penoplex, 4-5 dowels are enough. Install dowels with rods, the caps should be in the same plane with the insulation. The last step will be decorative finishing of the facade.

- When insulating the floor, foam plastic is laid on a reinforced concrete floor slab or prepared soil and secured with glue. Laying waterproofing film, on which a thin layer of cement screed is applied. After complete drying, the final floor covering can be installed.

- To insulate the roof, penoplex can be laid on the attic floors above or below the rafters. When constructing a new roof or repairing a roof covering, a thermal insulator is installed on top of the rafter system. The joints are sealed with glue. Longitudinal and transverse slats 2-3 cm thick are attached to the insulation in increments of 0.5 m, forming a frame on which the roofing tiles are attached.

- Additional roof insulation is carried out inside the attic or attic space. A sheathing frame is mounted on the rafters, on which penoplex is placed, secured with dowels. A counter-lattice is installed on top with a gap of up to 4 cm. A layer of vapor barrier is applied, followed by cladding with finishing panels.

- When insulating foundations, you can use the technology of permanent formwork made from foam panels. To do this, assemble the formwork frame using a universal screed and reinforcement. After pouring the foundation with concrete, the insulation remains in the ground.

For an overview of the comparison of penoplex with other materials, see the following video.

Of modern thermal insulators, penoplex is considered the most effective. This insulating material is made from extruded polystyrene, which automatically makes it cheap, but superior in technical characteristics, such as moisture absorption and sound insulation, and other heat insulators.

Production of penoplex and types of material

The production of penoplex is organized using the following technology: small polystyrene granules in a sealed chamber are exposed to high temperatures (130 0 C-140 0 C), as a result of which they melt, and after adding blowing agents they foam. Porophores are synthetic additives that, when heated, release nitrogen and carbon dioxide, which, after the penoplex cools, turn into frozen air bubbles, evenly distributed throughout the material.

Components of blowing agents for the production of extruded polystyrene foam (penoplex):

Cured foam may contain some synthetic fillers, the presence of which determines the direction of application of the insulation - for walls, foundations, etc. The most common additives are flame retardants to increase fire safety (reduce the degree of flammability), antioxidants to protect the material from oxidation outdoors, antistatic substances to relieve static and dynamic stress during insulation operation, light stabilizers (protection from the negative effects of UV radiation), modifying additives, etc.

Polystyrene foam is pressed under pressure from the extruder chamber onto a conveyor for final formation into slabs or blocks. The percentage of gases in the insulation reaches 98% of the total volume of the finished penoplex, so the products are light in weight with impressive dimensions. Dimensions for each functional line of insulation are given in the tables below.

Small size pores (0.1-0.3 mm) and their complete isolation from each other guarantees high thermal insulation performance of any brand of penoplex. For different construction projects, it is necessary to select the appropriate series and brands of insulation, since structures can be operated under different conditions:

- Brand “K” is designed for insulation of pitched or flat roofs and roofs. Specific gravity(density) series “K” - 28-33 kg/m 3;

- Series “C” - insulation for internal and external walls with a substance density of 25-35 kg/m 3;

- Brand “F”, basements and basements. Material with high moisture resistance, biological stability and specific gravity ≥37 kg/m 3 ;

- Penoplex brand "Comfort" is a universal series of insulation with a density of 25-35 kg/m 3. Direction of application – insulation of apartments, houses, basements, balconies and loggias;

- Brand “45” has the highest frost resistance and strength, specific gravity 35-47 kg/m 3. Designed for thermal insulation of road surfaces, runways, and other heavily loaded objects and structures.

A separate category produces sandwich panels, which are an improved thermal insulator for insulating attics and attics, facades and foundations of buildings. The sandwich panel has 2-3 layers and a cement bonded particle board as the bottom layer.

Operational and technical properties of penoplex, advantages and disadvantages

- Thermal conductivity – 0.03 Wm·0 C, the indicator does not decrease even with strong humidification;

- Water resistance – 0.4-0.6% when immersed in water for 24 hours and for a month;

- The vapor permeability of the material can be compared with the same indicators of roofing felt with a layer thickness of 20 mm;

- Chemical passivity: penoplex does not react to contact with building mortars and most aggressive substances. Substances with which penoplex contact is contraindicated: kerosene, acetone, formaldehyde, benzene, xylene, toluene, formaldehyde, methyl ethyl ketone, ether, diesel fuel, gasoline, tar, paints and epoxy resins;

- High mechanical resistance to stretching, compression, tensile forces and multi-vector pressure. The compressive strength of penoplex is 0.2-0.5 MPa;

- Biological neutrality - penoplex does not develop mold, does not decompose and does not rot;

- Wide range of operating temperatures - from -50 to +75 0 C. The temperature range for each brand is indicated on the packaging;

- Flammability groups for different brands– different, from G1 to G4, depending on operating conditions;

- Environmentally friendly material without the use of phenols and freons in the production;

- Guaranteed service life ≥55 years without noticeable loss in properties.

Advantages of penoplex:

- Thermal conductivity properties make it possible to use penoplex even in the Far North - multiple freezing/thawing cycles of the material do not affect its characteristics;

- Light weight makes transportation, warehousing, storage and insulation of the object easier, allows you to lighten the foundation and not strengthen the ceilings;

- Simple installation without the help of specialists and special tools - penoplex can be easily cut with a regular hacksaw or cutter;

- Safety and environmental friendliness - you can work with the material without personal protective equipment;

- Low cost of all brands of insulation. Even with a large consumption of heat insulator, the costs of its purchase and installation pay off in 2-3 seasons.

Disadvantages of penoplex:

- Low fire safety - material of any flammability group, even with fire retardant additives, can catch fire and release caustic toxic smoke;

- Low coefficient of vapor permeability, and under certain weather conditions - negative. Therefore, it is not recommended to use penoplex for internal insulation of house walls. To maintain optimal operating conditions for the insulation, it is necessary to provide forced-air ventilation in the house and ventilation of channels in walls insulated with penoplex;

- Destruction of material upon impact ultraviolet radiation- sun rays. It is necessary to protect the insulation layer with plaster or other methods;

- Due to the smooth surface, the adhesion of penoplex to mortars is quite low, so the insulation should only be attached to dowels or special expensive glue, but not to mortars.

Thermal insulation material “Wall” - properties and characteristics

The “Wall” brand is a renamed Penoplex 31 insulation with fire retardant additives, which has been improved for use in insulating “wet” facades, building foundations, plinths and basements, partitions and walls of houses outside and inside, roofs and attics. Characteristics of penoplex brand “Wall” are in the table below:

Insulation brand "Foundation" - parameters and properties

The “Foundation” brand is a renamed Penoplex 35 insulation without fire retardant additives, which can now be used to create thermal insulation for the bases and plinths of buildings, blind areas and basements. The strength, waterproofness and thermal conductivity of the "series" are its main advantages. The characteristics of the “Foundation” are given in the table below:

Penoplex "Roof" - properties and characteristics

Penoplex insulation of the “Roofing” series is a renamed material “Penoplex 35”, which is recommended for use in the insulation of pitched and flat roofs any design. The use of the “Roof” series makes the further operation of the roof as simplified as possible, since the reliability and long service life of the insulation minimize the possibility of repairing the roof surface. The popularity of this innovative insulating material is also due to the fact that greenhouses and summer gardens- such trends are now in fashion. Penoplex can withstand such high loads that it doesn’t care about soil loads of up to several tons. Characteristics of the foam insulation brand “Roofing” are in the table below:

“Comfort” is a universal brand of heat insulator

“Comfort” is a universal brand of heat insulator Brand of heat insulator “Comfort” - properties and characteristics

Penoplex "Comfort" is a modified and improved "Penoplex 31C" with universal characteristics. The material is actively used for insulation country houses, country houses and cottages. The high speed of installation and minimal labor costs popularize the insulation among private homeowners - it is used to insulate the subfloor, foundation and basement of a house, basement and roof, walls and partitions from the inside and outside of the building. Penoplex "Comfort" has high levels of moisture resistance and thermal conductivity. In the penoplex series line, the Comfort brand is recognized as universal.

Penoplex protects the soil from heaving when it freezes - when the soil is insulated with this material, the freezing point of the soil will rise. This series is optimal for insulating road and railway surfaces, runways and technical areas airfields. Comfort slabs retain their unique characteristics throughout the entire period of operation. Characteristics of the “Comfort” penoplex insulation brand are in the table below:

It is a misconception to think that penoplex and foam plastic are brother materials. Some properties of penoplex can be equated to the parameters of polystyrene foam, but not flammability and water absorption.

Manufacturers have long mastered the production of both non-flammable polystyrene foam and high-burning polystyrene foam. But the truth is that penoplex cannot spontaneously ignite, and in the zone open fire it will only melt, releasing carbon monoxide (CO) and carbon dioxide (CO 2) gases. If the fire is extinguished, the penoplex will not even smolder.

High-quality insulation becomes possible if the insulation is selected correctly. But this is not easy to do, because the market offers quite a lot of different solutions. One of the effective materials is penoplex. Before purchasing, you should find out how much material you will need. For correct calculations, you need to be aware of the dimensions of the penoplex. Proper execution of work helps create a warm microclimate in the home.

The types of penoplex produced make it possible to use it for insulation of almost any structures erected by humans

general information

Penoplex is a material consisting of foamed polystyrene, which is produced by extrusion. It can be used to solve a wide range of problems in the field of thermal insulation of objects. It is actively used not only during work in residential premises. This often happens when it is used to insulate industrial structures.

Thermal insulation of attic rooms and building facades is carried out more and more often using this product

Thermal insulation of attic rooms and building facades is carried out more and more often using this product This product was developed in the USA. A special technique, which involved the use of the extrusion method, made it possible to obtain a new solution with a uniform structure. The insulation contains many small cells with a finishing coating. Their size does not exceed 0.2 mm.

The heat insulator production technology involves mixing polystyrene in granules under conditions of high temperature and pressure. During this operation, a foaming agent is added. Oxygen dioxide is used as such, or a mixture consisting of two light types of freons is used. At the final stage of production, the remaining foaming agent in the cells is easily filled with ambient air.

In this video we will show you which insulation should be used for your home:

Main advantages

Penoplex is a popular material, as it allows you to effectively solve the problem of insulating buildings. It can be used to improve the thermal insulation of walls, foundations and roofs. In this solution, consumers are attracted by the following advantages:

Penoplex is used for thermal insulation of foundations, roofs, walls, floors and other structures for various purposes.

Penoplex is used for thermal insulation of foundations, roofs, walls, floors and other structures for various purposes. - No water absorption. The presence of this quality is due to the fact that the material has a special structure. Therefore, exposure to liquids does not lead to their penetration inside. Even its surface is impervious to moisture. Therefore, this factor is not negative for it and does not lead to the destruction of the insulator.

- Low thermal conductivity of penoplex. Experts classify it as a group of effective insulation materials. This is achieved to a large extent due to high rate thermal conductivity. For him it is 0.03 W/(m K). In this regard, the product is noticeably superior to many solutions.

- Low vapor permeability. The insulation is highly resistant to water vapor. The 20 mm thick plate resists steam penetration well.

- Durability. The service life of the heat insulator is at least 50 years. A significant point is that even with repeated cycles of thawing and freezing, the insulator does not lose its technical and physical properties. Therefore, it is applicable in any environment.

- Excellent compressive strength. It is due to the presence of a uniform structure in penoplex, which provides high compressive strength. It remains unchanged throughout the entire period of its operation.

Using this solution ensures ease of installation work

Using this solution ensures ease of installation work When carrying out insulation activities, specialists do not encounter any difficulties. Plates of material are easy to install. They can be easily adjusted to the required dimensions. There are no difficulties with processing penoplex. You can use a regular knife for this. Work may be carried out in any weather conditions. The use of any protective equipment is not required during the events.

Material marking

There are several varieties of this insulator. Naturally, depending on the marking of the penoplex material, the insulation characteristics will vary, as will its purpose.

Penoplex material has a high coefficient of compressive elasticity

Penoplex material has a high coefficient of compressive elasticity Penoplex-Wall. For this brand of product, the density varies between 25-32 kg/m³. The slabs are used to insulate the external and internal walls of buildings. The material can also be used to increase the thermal insulation of partitions and basements of buildings. Often the solution is used to improve sound insulation in rooms. After installation, the slabs are covered with a layer of lining, siding or decorative tiles.

Penoplex-Foundation. The description of the product indicates that its density is 29-33 kg/m³. Its main purpose is clear from its name. It is used for thermal insulation of the base of buildings, as well as surfaces in basements. The main characteristic of this type of insulation is resistance to moisture. Therefore, it is suitable for thermal insulation of shallow septic tanks. Treatment systems with this arrangement have a high risk of freezing.

Penoplex-Roof. The main use of this solution is related to the insulation of rafter systems and flat roofs. It is also good choice and for insulation attic floors. The density of the material is 28-33 kg/m³. This is precisely what explains its incredible lightness. Once installed, it does not create a large load on rafter system, therefore, there is no need to carry out work to strengthen the under-roof structure.

Penoplex-Comfort. This brand of popular product is used to insulate surfaces in apartments, balconies and loggias. It is also actively used for work in private homes and for insulating baths and saunas. Although the density of the material is insignificant, it is quite suitable for thermal insulation of surfaces in residential buildings. The operating conditions there do not imply a serious load on the penoplex. Therefore, its damage or destruction is excluded.

Penoplex-45. It is characterized by density indicators ranging from 35 to 47 kg/m³. The slabs can be used not only on balconies, but also for insulating floors in garages and parking lots.

Sheet sizes

Plates with a thickness of 2 to 10 cm are intended for insulation of internal walls and building surfaces

Plates with a thickness of 2 to 10 cm are intended for insulation of internal walls and building surfaces Having chosen penoplex, to correctly calculate the amount of material, you need to know the dimensions of the sheet. He has the following: length - 1200 mm; width - 600 mm. The thickness of penoplex is its main difference from other solutions. This parameter varies for insulation in the range from 20 to 100 mm.

For example, Penoplex-Comfort in one package can contain at least four slabs 20 mm thick, and their maximum quantity is 18 pieces of 100 mm each. If we talk about another brand - Penoplex-Foundation, then its thickness indicators are 50 and 80 mm. Packages contain five or eight slabs.

Often 50 mm insulation is used to complete the work.

Features of wall insulation

Interior work can be carried out with material no more than 2-3 cm thick, taking into account that the space of your home will be slightly reduced, just by the thickness of the insulation

Interior work can be carried out with material no more than 2-3 cm thick, taking into account that the space of your home will be slightly reduced, just by the thickness of the insulation This material can be used for a wide range of insulation work. It is often used to improve the thermal insulation of walls. If you need to make the façade of a building warm, then When carrying out activities, a certain sequence of stages should be strictly adhered to:

- The procedure for insulating external walls using penoplex begins with preparatory measures. The surface of the facade must be cleaned of dirt and dust. Remnants of old ones are also removed. finishing materials and paint and varnish coatings. After this, the procedure for leveling the walls should be carried out. For this purpose modern plaster mixtures. They are used if the walls have serious unevenness. After completing this operation, their surface must be treated with an antifungal compound.

- Next, the slabs are fixed to the wall by gluing. For this purpose they are used special compounds. Work can only be carried out if the surface of the facade is completely dry. The adhesive composition must be applied to the heat insulator.

- The next step is to fix the penoplex mechanically. Dowels act as fasteners. For every square meter of slab the norm is 4 pieces. When insulating the perimeter of windows and doorways, as well as carrying out work on the corners of the building, it is necessary to increase the number of dowels to 8 pieces.

- Upon completion of the installation of the slabs, it is necessary to apply the plaster composition. In order for the insulation to adhere well to the wall, you should use a brush to create roughness on the surface of the material. It is necessary to embed a reinforcing mesh of polymers into the first layer. Then the second layer is laid. After it has dried, you can move on to the next step - painting the walls.

Manufacturers of the material produce it under several brands, the name of which speaks for itself and greatly facilitates our choice.

Manufacturers of the material produce it under several brands, the name of which speaks for itself and greatly facilitates our choice. If you do not want to cover the walls with plaster, you can carry out the work using modern finishing materials or install a suspension system on the facade of the building. In the latter case, you must first create a frame.

Not all buildings have the opportunity for external insulation. In such cases, the material is laid from the inside. The technology for performing the work is similar. But it is necessary to install a foil film on the surface of the penoplex. It will act as a vapor barrier. Already on top of it, sheets of plasterboard are fixed, onto which the wallpaper is glued. To fix the sheathing on which the plasterboard sheets will be hung, it is necessary to use dowels. They are mounted in the wall through insulation. Thermal insulation of balconies and loggias occurs in a similar way.

If you plan to use drywall, it is best to purchase moisture-resistant sheets. When carrying out work on the loggia, you should not limit yourself to the walls; you also need to additionally lay the slabs on the floor. In this case, the effect of the work will be maximum.

Roof thermal insulation

Work begins with laying insulation on the rafter system

Work begins with laying insulation on the rafter system Measures to insulate this structural element are carried out either during construction or during the reconstruction of an old facility. Insulation is often carried out to turn a cold attic into a living space. Before starting work, you need to prepare the following materials:

- metal tiles or other roofing solution;

- sheathing;

- vapor-permeable moisture-resistant membrane;

- insulation;

- internal lining;

- rafter structure.

Work begins with laying insulation on the rafter system. The material is placed in a checkerboard pattern. After this, you need to lay a vapor-permeable membrane on it. Next, using longitudinal slats with a thickness of at least 40 cm, the heat insulator is fixed. In order to ensure ventilation between it and the roof, it is necessary to maintain a step of 300 mm.

After this, you can proceed to securing the transverse slats. Then, after placement, the roofing material is fixed on them. It is permissible to use metal tiles or any other.

Roll solutions for continuous flooring can be a good alternative

Roll solutions for continuous flooring can be a good alternative Penoplex differs from another popular insulation product - penoflex - by its high cost. However, this disadvantage is compensated by its excellent characteristics. It is ideal for use under plastering systems.

Penoplex is one of the best materials for creating effective thermal insulation. If you constantly feel cold in your home, then using it can solve this problem. There are significant costs involved in carrying out the work. But they are offset by savings on heating rooms. Proper implementation of the procedure minimizes heat loss and ensures comfortable living.

If previously the range of thermal insulation materials was not rich enough, today buyers are faced with a wide selection of insulation materials with different properties and performance characteristics. This means that pick up suitable option Can a homeowner with any budget. Today, penoplex is rightfully recognized as one of the most popular materials, which is in great demand and occupies a leading position in the market of thermal insulation coatings. Today we will look in detail at what it is, find out where it is used and how this popular insulation is installed.

What it is?

Surely every person has heard about this at least once in his life. building material like penoplex. However, not every consumer knows what lies under this name.

Penoplex is a well-known tradename high quality extruded polystyrene. Today this material is the leader in the insulation market. They often cover walls, ceiling structures, roofing bases and even floors.

Features and production

Penoplex is high-quality foamed polystyrene. This type of material is produced by extrusion.

A similar production process was developed more than half a century ago in American laboratories. Thus, a completely new material appeared, the structure of which consisted of closed microscopic cells. From the very beginning, their dimensions did not exceed 0.2 mm. In a single structure, these components created a neat and uniform surface without potholes or differences.

The granules of this polymer contain a special additive that has a foaming effect. This component is combined with granules under pressure or under heating conditions to a certain temperature. The result is a mass that is then passed through an extruder.

Foaming components (as a rule, they are represented by carbon dioxide or a mixture of light freons) are non-toxic and absolutely safe from an environmental point of view. In addition, these components are not flammable.

When the manufacturing process is completed, all auxiliary components are replaced with air from the environment.

The result is a high-tech thermal insulation material with excellent performance characteristics. With its use, your home becomes much warmer and more comfortable - a comfortable microclimate is created that you don’t want to leave.

The main distinguishing features of penoplex are:

- low level of thermal conductivity;

- good strength characteristics;

- minimum level of moisture absorption.

As a rule, this insulation is packaged in film, which protects it from aggressive sunlight. Thanks to such packaging, such material can be easily stored outdoors. However, it is worth considering that even if there is plastic packaging, the product must be additionally protected from ultraviolet radiation.

Under the influence of UV rays, this insulation may lose the integrity of the top layer.

Advantages and disadvantages

Penoplex is a popular material that is in great demand. Its popularity is due to many positive qualities:

- Penoplex is a hydrophobic material.

- It is light in weight, so it is quite easy to work with it. Moreover, you will not spend a lot of money on transporting this material.

- Penoplex has excellent strength characteristics. It is not so easy to damage this material - it is not susceptible to mechanical defects.

- The composition of this thermal insulation coating is anti-corrosion, so it can be safely laid on bases consisting of the most different materials.

- The installation of penoplex can be started in almost any conditions. You don't have to wait for the right moment to start installing the slabs.

- This insulation does not attract the attention of insects and rodents, which are usually quite difficult to get rid of.

- Penoplex is an environmentally friendly and safe material - it does not have a negative effect on human health.

- Penoplex is easy to install. With a minimum set of knowledge, you can install this insulation yourself.

- Many buyers prefer this insulation because it has an affordable price.

- Penoplex has minimal water absorption.

- Penoplex does not cause allergic reactions.

- This material is quite strong in compression.

- This insulation is universal - modern manufacturers produce high-quality coatings intended not only for walls, but also for floors and roofing “pies”.

- Penoplex is not subject to rotting, which once again confirms its durability and resistance to wear.

- This material has a long service life.

- Such extruded polystyrene can be used both in the construction of new and in the restoration of old buildings.

Penoplex is not an ideal heat-insulating material. It has its own weaknesses, which you should also be aware of if you decide to purchase such products for your home. Among them:

- This material is flammable. It burns and actively supports combustion.

- Penoplex does not withstand contact with solvents. Under their influence, polystyrene is destroyed and deformed.

- Not all manufacturers offer penoplex at affordable prices. Many stores sell expensive products.

- Another disadvantage of penoplex is its low vapor permeability (in certain situations). For example, if this material is not installed correctly or is exposed to unfavorable conditions, then condensation may accumulate in it (from outside). This is why this material becomes susceptible to the formation of fungus and mold. To avoid such problems, the room must be provided with good ventilation, otherwise normal air exchange will be hopelessly disrupted.

- This material for high-quality thermal insulation cannot boast of good adhesion. It has an absolutely smooth surface, so gluing it to walls and ceilings is often not very convenient.

- It is recommended to protect this thermal insulation material from direct sunlight. Under their influence, penoplex may undergo deformation or damage to the top layer.

- To make extruded polystyrene more resistant to fire, special substances - fire retardants - are added to it during the production process. Materials with such additives become self-extinguishing, but when burning or smoldering, this insulation will emit black clouds of smoke containing toxic compounds.

Of course, penoplex has many more positive qualities than negative ones.

Many problems associated with this material can be avoided if it is installed correctly.

Specifications

The main characteristics of penoplex include:

- low level of vapor permeability, the coefficient of which is 0.03 W/mºK;

- high strength characteristics (both compression and bending);

- low level of moisture absorption - no more than 0.2-0.4% by volume per day;

- low degree of vapor permeability - the coefficient of this parameter ranges from 0.007 to 0.008 mg/mh·Pa);

- service life exceeds 50 years;

- combustion resistance;

- environmental Safety;

- wide temperature range of application, which ranges from -50 to +75 degrees.

Thanks to its technical characteristics, penoplex has become a popular and sought-after material. It is difficult to damage or break. However, unfortunately, it is flammable.

Different types of penoplex belong to different classes flammability:

- materials for roof insulation - class G3;

- for wall insulation – G3;

- for foundations - G4;

- universal insulation - G4;

- road materials - G4.

In addition, all of the listed thermal insulation materials have different compression densities, for example:

- for roofing – 0.25 MPa;

- for walls – 0.2 MPa;

- for the foundation - 0.25 MPa;

- universal – 0.2 MPa;

- road – 0.50 MPa.

Extruded polystyrene foam boasts good resistance to various chemicals and materials. These include:

- antiseptics designed to protect natural wood;

- bitumen-based mixtures;

- cement;

- lime.

Penoplex can be destroyed by foreign materials that contain a component such as a solvent. Such products soften polystyrene, which then leads to its significant shrinkage.

When working with penoplex, you should avoid the following mixtures:

- paint thinners;

- coal tar (and any of its derivatives);

- solvents such as acetone and ethyl acetate.

Brands and sizes

Currently, the most popular and High quality products with the following markings are common:

- 45 C;

Let's look at each marking in detail:

- Penoplex 31. This is a type of material that does not have the highest strength characteristics. Such coatings are not recommended for use in areas where there is heavy load. As a rule, such penoplex is used to insulate containers and pipelines.

- 31 C. Materials that have this marking also cannot boast of sufficient strength. They are most often used to insulate walls inside a home. This penoplex differs more from class 3 raw materials high level flammability.

- 35. Thermal insulating material with this marking has good strength characteristics. In addition, it is characterized by excellent insulating qualities. Using such coatings, foundations, floors and pipes running underground are insulated.

- 45. There is also penoplex marked 45. This type of material is used for insulating runways and constructing road surfaces. Moreover, such insulation materials are ideal for finishing floors in production areas and other similar premises.

- 45 C. The material with this marking has almost the same parameters as Penoplex 45. It is quite reliable and durable. However, such insulation is more often used for finishing walls in industrial areas.

- 75. This marking belongs to special materials that have a density of 40-53 kg/m3. Such raw materials are most often used in the construction of runways located at airfields.

Penoplex, belonging to the “standard” class with a density of 25-31 kg/m3, has the following technical characteristics:

- width – 600;

- length – 1200;

Comfort type material (28-33 kg/m3) has the following dimensional parameters:

- width – 600;

- length – 1200;

- thickness – 20, 30, 40, 50, 60, 80, 100.

Foundation material with a density of 29-33 kg/m3 has similar dimensions. As for the insulation “45” (35-47 kg/m3), its data is as follows:

- width – 600;

- length – 2400;

- thickness – 40, 50, 60, 80, 100.

These parameters are indicative. First of all, the sizes of extruded polystyrene depend on the manufacturer who released them to the market.

Nowadays you can find non-standard canvases in stores.

Types and properties

Penoplex is a popular and in demand material. It is represented by many modifications, each of which has its own markings and designations. Currently, there are several varieties of this thermal insulation coating.

"Wall"

The density of such extruded polystyrene can range from 25 to 32 kg/m3. This heat-insulating material is perfect for installation on external and internal floors. In addition, penoplex “wall” can be used in the design of partitions and plinths. Thanks to this material, the sound insulation characteristics of the room are increased.

"Foundation"

No less popular today is a material such as penoplex “foundation”. Its density varies from 29 to 33 kg/m3. You can safely use this coating if you want to insulate the foundation and upper part of the basement. This material is highly dense and water resistant. In addition, this insulation is often used for thermal insulation of septic tanks that have a significant depression.

"Roof"

Another common and popular material is foam roofing. Similar products are produced directly for insulating rafter or flat roof types. Also, material from the “roofing” category can be used to insulate attic structures. The density of this brand, as a rule, ranges from 28 to 33 kg/m3. This material is lightweight and does not place a large load on the roof sheathing.

"Comfort"

Comfort products are in great demand today. Such materials have a density of 25-35 kg/m3. They are used to insulate walls in apartments. For example, this could be the area of a balcony or loggia. It is acceptable to use such a coating in baths and saunas.

"Geo"

Penoplex "geo" is an alternative to materials belonging to the "foundation" class. Such coatings are more often used in industrial and civil applications. construction work. It is worth noting that slabs of this insulation are often used for cladding floors, foundations and other similar

"The basis"

Penoplex from this category has an optimal density that allows it to be used in a wide variety of construction work. Such insulation is laid on the floor, walls and roof bases. Penoplex “base” is popular due to its durability and versatility of use - it is often used in both civil and industrial construction.

"Pitched roof"

Penoplex “pitched roofing” was developed specifically for roof insulation. This coating is ideal for installation on the foundations of low-rise buildings. As a rule, this thermal insulation material has a thickness of 10 and 15 cm.

"Facade"

The name of this type of penoplex speaks for itself. It is used for insulation of plinths, facades, external parts of ceilings and partitions. This material has a special milled surface on which plaster can be applied much easier and more reliably. The thickness of the penoplex “facade” is 20-100 mm.

Scope of application

Penoplex is recognized as one of the most popular and high-tech materials, so it is used in many cases:

- This type of thermal insulation material is used to insulate walls, roofing bases and floors.

- Many buyers choose penoplex for foundation insulation.

- There are also materials that are used in road construction and the construction of runways.

- Some types of insulation are installed in balconies, loggias, baths and saunas.

The main thing is to choose the material of the appropriate class and type.

What can be replaced?

There are times when penoplex is not available in stores for some reason. Slightly less often, consumers themselves refuse to purchase this material due to high cost or flammability. Many people wonder what can replace this insulation in such situations.

A good alternative to penoplex is a domestic material called “Technoplex”. This insulation is in great demand today and is a strong competitor to the branded products of the Penoplex brand. It is good because it fits seamlessly on bases made of a variety of materials. In addition, it can be safely laid on the floor, since it can be combined with a “warm floor” system.

Currently, Technoplex is produced using special nanotechnology. In this case, graphite is used, which significantly reduces the level of thermal conductivity of the insulation, but at the same time increases the rigidity and wear resistance of the plates.

This material has a silver-gray color, which distinguishes it from penoplex. However, Technoplex has the same positive qualities as extruded polystyrene. That is why these materials are interchangeable.

"Technoplex" is manufactured in a tile format. Such thermal insulation materials can have the following thickness:

- 100 mm;

- 50 mm;

- 40 mm;

- 30 mm;

- 20 mm.

At the same time, slabs of such insulation are produced with grooves and tenons, with the help of which they can be easily and quickly assembled, forming a neat seamless coating. Due to the absence of gaps on such an insulating layer, “cold bridges” do not appear on the bases.

After installation is completed, material such as Technoplex must be covered with decorative finishing materials.

This requirement is explained by the fact that aggressive ultraviolet rays can negatively affect the quality and integrity of the insulation, so it must be “hidden” behind other coatings.

Another popular analogue of penoplex is “Polyspen”. This insulation is also produced in Russia. It is currently available in three variations, having various technical characteristics, which include thermal conductivity, strength, as well as the level of flammability and compression:

- "Polyspen 45";

- "Polyspen 35";

- "Polyspen universal."

This analogue of penoplex contains a fire retardant. Thanks to this component, “Polyspen” is less flammable. Such materials are produced in the form of slabs with a thickness of 20, 30, 40, 50, 60, 80, 200 mm. Thanks to this choice, it will be possible to select insulation for a specific area.

Penoplex can also be replaced with the following thermal insulation materials:

- Styrex. This material is quite strong and durable. Its thermal conductivity level is slightly lower than that of penoplex.

- "Extrol". This is another polystyrene foam insulation that goes through extrusion during the manufacturing process. It has much in common with penoplex, but is produced in the form of cylindrical elements, convenient for insulating water supply systems.

- Styrofoam. Foam plastic (without extrusion) is often used instead of penoplex. It is much cheaper than extruded polystyrene, but is less strong and durable.

If the insulation will be constantly exposed to high temperatures, then it is better to give preference to mineral wool. This type of thermal insulation material is one of the most popular and in demand today.

By her own mineral wool- This is a fibrous insulation of inorganic origin. This insulation has many positive qualities, for example:

- fairly high thermal insulation performance;

- waterproof;

- resistance to aggressive chemicals;

- good air exchange;

- excellent sound insulation characteristics;

- fire resistance;

- long service life (25-50 years);

- environmental friendliness.

Installation technology

You can lay penoplex on a particular base with your own hands. To do this, you do not need to have a wealth of experience and cunning knowledge. The main thing is to adhere to simple technology and use high-quality materials.

It was previously mentioned that installation of extruded polystyrene foam can be done both inside and outside the home.

Let us consider step by step how to install this material in all of the above cases.

Inside the building

Penoplex can be installed in the interior of the house. All work is done as follows:

- First you need to carefully prepare the base for laying insulation. In this case, you need to remove the previous materials from the walls (any wallpaper, paint coatings and others), without missing a single section.

- Next, the bases need to be protected from fungus and mold. If they have already appeared, then you should get rid of them. For this, it is recommended to use special antiseptic compounds. After this, it is worth carrying out sanitary treatment. To do this, you can use almost any product that has an antibacterial effect.

- Pay attention to the evenness of the bases. So, the walls should not have significant differences and potholes. You need to get rid of any defects - level the bases, and then prime them with a high-quality composition.

- Next, you can proceed to assembling the base profile. Such structures are most often used to facilitate the installation of insulation. In addition, the profile parts will protect thermal insulation coating from unfavorable external factors.

- The base profile should be attached to the base using dowel nails. In order for the insulation to fit more tightly to the ceilings, they can be supplemented with spacer washers.

- Be sure to ensure that the width of the profile matches the thickness of the penoplex.

- Using joining plates, the final components of the structure must be joined to each other. Don't forget to leave a small gap between them (about 2 cm).

- Now you can attach the polystyrene foam boards. Apply a layer of glue to the penoplex (around the perimeter of the slab and in its center).

- Many craftsmen recommend not saving at this stage and thoroughly coating the entire polystyrene foam board with an adhesive solution. After this, the insulation must be pressed against the profile. If protruding particles of glue appear on the materials, they must be removed immediately.

- If there are small gaps between the materials, you can get rid of them by filling them with inserts from pieces of expanded polystyrene. Not everyone uses polyurethane foam in this situation, since such sealing can cause cracks to appear.

- After this, it remains to make the final fastening of the thermal material to the base. When the glue has completely dried (usually this takes about 3 days), work can continue. You need to secure the insulation with mushroom dowels. Hardware should be placed in the middle of the slabs, as well as along their perimeter. However, here it is necessary to calculate that in the end all the sheets of penoplex will be connected.

It is worth keeping in mind that insulating a home from the inside is not always appropriate or practical.

The main disadvantage of such work is the reduction in living and free space due to the thickness of the materials, as well as the profile design.

Outside

According to experts, external insulation of a house is more practical and convenient. At the same time, free space is not hidden, and dirt and dust remaining during work do not accumulate inside the premises.

For external insulation, penoplex with a thickness of 80-100 mm is most often used. The process of installing thermal insulation material in this case is in many ways similar to internal insulation.

First, the façade of the house needs to be leveled. If there are cracks or potholes on it, then you must get rid of them - repair them and then prime them.

Penoplex is glued to the facade base in the same way as for internal insulation of a home. Fastening to dowels occurs in a similar way.

If you want to plaster the facade in the future, then preparatory work you need to glue the reinforced mesh.

If you want to decorate the house with siding or PVC panels, then you need to take care of the vertical guides in advance in order to securely fasten them. In this case, an additional layer of vapor barrier material is not required.

On the roof

- Penoplex is ideal for strengthening the roof. Not only beginners, but also experienced craftsmen turn to this insulation. Insulation boards can only be laid after the roof frame structures have been prepared

- (lathing). On the lower section of the rafters near the insulated area, you need to nail a block. Its thickness should be the same as the thickness of the insulation. This part will play the role of a starting rail. This element must be placed at an equal distance from the edge (along all rafter supports). Starting from the starting rail, you need to lay extruded polystyrene slabs.

- This should be done in a checkerboard pattern. The thickness of the laid layer, first of all, depends on the geographical location of the facility under construction. However, experts always recommend laying insulation not in 1, but in 2-3 layers. At the same time, it is very important to properly seal all joints.

- After this, you should install a sheathing intended directly for installing the roofing material. For this purpose, a structure assembled from bars secured in accordance with a certain step is quite suitable.

- You can also use solid coatings made from OSB. Such bases are ideal for installation soft species roofs. Thermal insulating material should be attached tightly to the ridge.

The gap should only be left when installing the roof itself.

For comfortable stay In a house at any time of the year, you should immediately take care of its high-quality thermal insulation. It will help out by making the house warmer in winter and cooler in summer. The construction market provides a large selection of materials for thermal insulation, and each consumer can choose an option to suit their taste. The most acceptable insulation in terms of price, quality and ease of installation can be called penoplex.

Features and Specifications

Penoplex boards are similar in properties to polystyrene foam, but have a number of advantages. The main thing is their high strength and density of the material. Of course, some still prefer older methods to insulate walls. For example, brick. It is worth mentioning that 20 mm thick penoplex replaces brick wall, in which this figure is 370 mm. And if we compare slabs with a thickness of 50 mm, the superiority will be even greater: they correspond brickwork at 925 mm.

Three types of material under consideration can be distinguished:

- "Penoplex 31". Due to its poor resistance to compression, this type is mainly used for insulating various pipes.

- "Penoplex 35". The most popular type, due to the presence of a special substance that increases the material’s resistance to combustion. It is well suited for thermal insulation of building envelopes and foundations.

- "Penoplex 45". Compared to other options, this one is the most durable and can withstand high loads. In addition to building houses, Penoplex 45 is often used to create roads. This solution prevents swelling of the road surface when freezing, this is especially important when operating runways. Presented in a narrower range (40–150 mm).

In addition to this classification, there is another division of penoplex. The name of the insulation indicates the scope of its application, which makes the choice easier.

"Penoplex Comfort"

Most universal insulation. Suitable for foundations, walls and roofs. Insulation of this category is especially in demand for thermal insulation of balconies and loggias. The main disadvantage of the material is its high flammability; it is not allowed to be used in places where open fire is possible. Its main parameters correspond to insulation of category “31”.

"Penoplex Foundation" (series "F")

It is used for insulation of underground buildings, foundations of any buildings, as well as the basement of the house. It combines many excellent characteristics: minimal water absorption (especially important in areas with shallow groundwater), resistance to heavy loads ( long time does not subsidence, more than 50 years). "Penoplex F" is also used for improving garden paths on a sand-cement base.

If our ancestors who built cities had such wonderful material at their disposal, they would have been lucky enough to build houses that were insured against their subsequent subsidence. Cracks would not appear in the walls of buildings, and the foundation would not collapse under the influence of soil waters.

When arranging and protecting the base with penoplex foam of the “F” series, it would be useful to take care of strengthening the floor screed of the house. It is important to highlight two points here:

- Strengthening the screed with reinforcement.

- Using Penoplex Foundation sheets at the stage of pouring the screed. The size of the sheets will dictate the area of the house: the larger the material, the fewer joining seams, and therefore the fewer “cold bridges” through which heat will escape from the house. The concrete floor obtained in this way will provide increased comfort. It will have low thermal conductivity thanks to penoplex, which means it will retain heat inside the house.

The blind area of the house can also be protected using Penoplex Foundation. It is better to spend money once than to watch with tears in your eyes how your home is destroyed by heavy rains.

"Penoplex Roofing" (series "K")

Technical characteristics are the same as those of Penoplex Foundation, only the compressive strength coefficient is lower (material density is 28–33 kg per m3). However, the roof does not experience the same loads as the foundation. Due to its low density, the material does not weigh down the rafter system.

"Penoplex Wall" (series "C")

"Penoplex Geo"

This material is very popular among industrial organizations. It is ideal for floors under cement-sand screed. The thickness of the slabs varies from 20 to 100 mm.

The table shows the main types of insulation and its characteristics:

After studying the basic parameters and properties of foam boards, you can determine its other characteristics and operating conditions. The main technical characteristics of penoplex include:

- Low water absorption (0.4% when in contact with a humid environment for 24 hours, or 0.5% when in water for about 1 month). Water can penetrate only in places where the penoplex itself is damaged, which is formed during installation.

- Low thermal conductivity (coefficient is 0.03 W/ (m*K)). It is provided due to its cellular structure and lack of water absorption.

- Low vapor permeability of the material (0.007–0.008).

- Durability (more than 50 years) - not susceptible to fungus and rot, but this is only provided that there were no violations of technology during the installation of the slabs.

- Resistance to thermal factors (provided by the content of penoplex fire retardants, which reduce the flammability of the material).

- Wide operating temperature range (from -100 to +75 degrees).

- Resistance to mechanical factors - resists compression. Under heavy loads (higher than the performance characteristics of a certain type of penoplex allow), small dents up to 1 mm deep may appear.

- Due to their light weight, foam boards are easy to install. Due to their weight, they can easily be raised to great heights, and they themselves do not weigh down the structure.

Despite these advantages of the material, it is worth highlighting the existing disadvantages:

- Despite the material’s sufficient resistance to fire, it still burns (flammability level G3–G4), and toxic gas is released;

- The material is not resistant to direct sunlight. When it comes into contact with UV rays, penoplex can change its characteristics and at the same time emit toxic fumes.

- Penoplex does not perform a soundproofing function; this must be taken into account when insulating a house.

Standard parameters

Penoplex is available in the form of a slab. The dimensions of these penoplex slabs are standardized, with the length varying between 1200 and 2400 mm, with a width of 600 mm. They vary in thickness, which ranges from 20 mm to 10 cm (in increments of 10–30 mm).

The thickness of the material is determined by its area of application. So, “Penoplex Foundation” starts from 50 mm. To insulate internal walls, the thickness of the slabs ranges from 2 to 10 cm. When working with internal walls It is worth considering that the area of the room will be reduced. Therefore, it is worth choosing slabs with this indicator of 2–3 cm.

For external buildings, for example, for a roof, a sufficient thickness is 4–6 cm. To insulate external walls, this indicator for slabs should be in the range of 8–12 cm. The density of the material depends on the degree of mechanical pressure on the slab.

How to choose?

To choose which penoplex you need, you need to decide what kind of work it is needed for - insulating walls, roofing or foundations. There are a number of parameters to consider.

By purpose

- Penoplex Comfort is well suited for insulating foundations, walls, and floors.

- To insulate walls (both external and internal), plinths, partitions to effectively save heat and reduce heating costs - you should choose Penoplex Wall.

- For the construction of the foundation of a house or the construction of premises for a basement, “Penoplex Foundation” is suitable, which has high water-repellent properties and increased strength.

- If roof insulation is necessary, there is Penoplex Roofing. It is suitable for both flat and pitched structures. Due to the lightness of the material, the building structure does not become heavier.

By density

Before purchasing a thermal insulation material, the buyer thinks about its density, because this indicator can be used to judge the strength of the material, its weight and thermal conductivity.

- The density of Penoplex Comfort is in the range from 25 to 32 kg/m3.

- A less versatile type, which has higher strength, can be called “Penoplex Roofing”. The density of the material is 28–33 kg/m3.

- For Penoplex Foundation this figure is 29–37 kg/m3. For this type of material, this parameter is especially important. The degree of resistance to mechanical factors (compression) depends on it.

- “Penoplex 45” has the highest density; it ranges from 35 to 47 kg/m3.

By sheet thickness

- The thickness of Penoplex Comfort varies from 20 to 100 mm. Each type has its own purpose, for example: penoplex with a thickness of 50 mm is mainly used for insulating the foundation or blind area.

- The thickness of the “F” series penoplex starts from 50 mm; these are the overall dimensions that should be used for insulating underground buildings and foundations in any house.

- When purchasing penoplex, you should pay attention to the labeling of the product, the safety of the packaging, and the technical characteristics of the material.

- It is worth buying 10% more material from the measured initial quantity, in case it is rejected during use.

- It is necessary to work with the material carefully, since if its integrity is damaged, water may get inside, which will shorten the service life of the material. It is better to use the services of professionals or read the instructions yourself and work with penoplex correctly.

- Girls and women almost always associate white shoes with a wedding dress, although the white color of shoes has long been no longer required. A...

- Types of speech: description, narration and reasoning

- Martyrs Tatiana. Moscow Church of St. Martyrs Tatiana Temple of the Martyr Tatiana at Moscow State University schedule

- Milotici: return of the Russian village Moravov Alexander Viktorovich

- Why you shouldn't cry in front of the mirror

- Recommendations: what to grease the pies to make them rosy and appetizing

- Actors Spiderman Aunt May Aunt May in Spiderman

- Making sounds for children Lessons on making sounds for children

- Criteria for preparing an act on write-off of motor vehicles

- Pink salmon in the oven - delicious and easy recipes for baked fish Pink salmon fillet baked with vegetables

- What does a lizard tattoo mean?

- Deciphering the natal chart of the house

- What does mulberry help with?

- Photo report “Birthday of Samuil Yakovlevich Marshak in the group”

- Breathing at high pressure Breathing correctly at high pressure

- Bryansk State University named after

- Tasks to test spelling and punctuation literacy

- Application...burning, grow...sti, to...sleep, m...roll, warm...up, sk...roll,...

- The Forex Economic Calendar is a reference book for every trader, regardless of trading experience and level of professionalism, and especially...

- Representatives of the arachnid class are creatures that have lived next to humans for many centuries. But this time it turned out...