Materials for exterior finishing of facades of private houses. Selecting finishing materials for the facades of private houses

Exterior decoration of the house, the options of which are presented in a large assortment on a modern construction market, can transform the walls of any building, both old and new. But, Besides, Right installed material will perfectly protect surfaces from the influence of external factors, preventing their erosion and destruction.

If the house is just being designed, it is recommended at this stage to foresee in advance how and how its walls will be decorated. If a decision is made to protect and renovate the façade of an old building, then this issue needs to be approached more responsibly, since you will have to select the finish not only according to its aesthetic and quality characteristics, but also according to its compatibility with the wall material. Therefore, you should familiarize yourself with various options finishing to make it easier to decide on the right choice.

At what stage of construction is facade finishing carried out?

Before moving on to considering various facade finishing materials, it makes sense to immediately decide at what stage of construction the installation work should be carried out. This is also important because finishing installed at the wrong time can be damaged during the installation of other building elements.

- So, first of all, Finishing work are carried out only after window and door blocks are installed and secured in the openings of the house.

- Secondly, almost any structure shrinks during the first year after construction, sometimes quite significantly, which can significantly damage the façade finishing. Therefore, final finishing activities are recommended to be carried out after this period.

- After a year of shrinkage, before finishing, all surfaces of the building should be checked for verticality and horizontality. If significant distortions appear, the wall may have to be leveled using plaster or lathing, depending on the material from which the house was built and the chosen finish.

- It is recommended to carry out facade work at moderate temperatures, approximately from +5 to +25 degrees, at which materials are in their natural state without expanding or contracting.

- Some of the finishing materials have considerable weight, so they will significantly increase the load on the foundation, and this factor is especially important to take into account when finishing an old house. If doubts arise on this issue, it is best to invite a specialist who can calculate the possible additional load on the foundation of the house and its admissibility.

Plaster finishing of the facade

Brick facade finishing

Brick cladding is the only finishing method that can be carried out before window and door frames are installed in the openings, so with this approach another durable layer of the wall is built, and when installing frames or frames, they will not harm the finishing in any way.

Quite often, an insulating material, such as mineral wool, is laid between the main wall and the facing layer of brick, or the gap between them is filled with polyurethane foam, expanded clay or vermiculite backfill.

Artificial stone can be correct and irregular shapes and is made in the form of tiles or fragments of “wild” stone with chaotic chips on the outer surfaces.

If the stone is made and laid in strict accordance with existing technological recommendations in this regard, then it is difficult to distinguish it from natural one. True, the artificial material will have to be periodically tinted, and possibly covered with a special façade varnish.

Facade finishing with panels

Facade panels are made from different materials- it can be metal, polyvinyl chloride, fiber cement or wood, so to speak, “for every taste and budget.” Panels are produced in different sizes, so it is possible to choose exactly the option that will be most convenient for installation. On sale you can find single-layer and multi-layer finishing boards, therefore, if there is a need, along with finishing, to also insulate the walls, then it makes sense to choose sandwich panels in which thermal insulation material is prudently installed.

The panels reliably protect walls from external natural influences, keeping them without damage long time, as they are combined into a single covering.

Modern façade panels have high strength and resistance to corrosion and ultraviolet radiation. They are great for cladding the walls of old houses, transforming them beyond recognition, since many of them imitate natural stone, wood, brick and other finishing coatings.

Metal panels with polymer coating

Metal panels are made from aluminum or galvanized steel. Their surface can be smooth, profiled or even textured. Thickness metal sheet sometimes up to 0.55 mm. The surface of the panels can be coated with different polymers - plastisol, glossy or matte polyester, as well as pural.

This type of panel is characterized as follows:

— their service life is 30 years or more;

— high frost resistance is expressed;

— resistance to corrosion processes;

— moisture resistance;

- absolute non-flammability;

— ease of installation;

- variety color solutions;

— resistance to acids and alkalis;

— impact resistance – up to 50 kg/cm².

The disadvantage of these panels is the complete lack of insulating and soundproofing qualities.

Vinyl panels

Vinyl facade panels can be called the most popular material for surface finishing, as they have excellent appearance and the variety of options offered

Prices for wooden lining

The panels are assembled together into a single wall cladding, most often using locks or latches, and the cladding is fixed to the wall (or to the frame structure) using dowels or self-tapping screws.

The obvious advantages of this finishing material include the following qualities:

— long service life, about 30 years;

- operating temperature from -50 to +50 degrees;

— excellent water resistance;

— ease of processing and installation;

— low weight of the material – about 5 kg/m²;

— complete inertness to corrosion and biological processes;

— relatively low thermal conductivity – about 0.16 W/m׺С;

— high resistance of the material and coloring pigments to ultraviolet rays.

The disadvantages of such cladding include the fragility that polyvinyl chloride acquires when low temperatures, therefore there is a risk of chipping and cracking under intense mechanical stress.

Facade two-layer thermal panels

Equipped with a layer of polyurethane foam, they have high thermal insulation qualities, since this insulating material has a closed cellular structure consisting of 96% air. The thickness of the thermal insulation layer can be from 40 to 100 mm, on top of which a decorative cladding made of polyurethane, polyvinyl chloride or metal is fixed.

The “advantages” of this facing material include the following qualities:

- fairly long service life - from 30 to 50 years;

— high frost resistance;

— low thermal conductivity of 0.028 W/m׺С, which helps to minimize heat loss through the walls of the house;

- low moisture absorption;

— resistance to external influences and the emergence of microflora colonies;

- operating temperatures from -48 to +100 degrees;

— small mass of panels, amounting to only about 5 kg/m²;

— the cladding requires virtually no maintenance;

- simplicity is noted installation work. This is even more important because performing one installation operation immediately provides a solution to the problems of both finishing and insulating the walls.

The disadvantage of cladding is that the material melts when exposed to open flame or high temperatures. But, at the same time, it does not contribute to the spread of fire, since it is self-extinguishing.

Facade sandwich panels

Sandwich panels consist of three layers - two rigid outer sheets, which are made of metal, magnesite board, fiberboard or PVC, and a layer of insulating material laid between them - mineral wool or polyurethane foam is most often used as it.

Such a panel is not only a reliable protective and decorative finish for walls, but also insulation and sound insulation for the walls of the house. The main performance characteristics of this facing material largely depend on the type of insulation material and its thickness:

Some characteristics wall sandwich panels– shown in the table:

| Panel thickness (mm) | Specific gravity (kg/m²) | Thermal conductivity kW/ (m²×ºС) | Fire resistance index GOST 30247-94 (EI) | |||

|---|---|---|---|---|---|---|

| MV | PPU | MV | PPU | MV | PPU | |

| 50 | 14.1 | 9.5 | 0.84 | 0.78 | EI15 | EI15 |

| 60 | 15.2 | 9.7 | 0.71 | 0.65 | EI30 | EI15 |

| 80 | 16.3 | 10.1 | 0.57 | 0.49 | EI45 | EI15 |

| 100 | 18.5 | 10.4 | 0.47 | 0.4 | EI60 | EI15 |

| 120 | 20.6 | 10.9 | 0.38 | 0.32 | EI60 | EI15 |

| 140 | 22 | 11.3 | 0.35 | 0.287 | EI70 | EI15 |

| 150 | 24 | 11.5 | 0.32 | 0.27 | EI90 | EI15 |

| 180 | 27.8 | 12.1 | 0.26 | 0.23 | EI90 | EI15 |

| 200 | 30.5 | 12.5 | 0.2 | 0.2 | EI90 | EI15 |

| 250 | 37.2 | 12.9 | 0.16 | 0.19 | EI90 | EI15 |

In this table, some materials and indicators are designated by letters that have the following meanings:

— MV – mineral wool (usually basalt);

— PPU – polyurethane foam.

Fire resistance index EI - loss thermal insulation properties and violation of the integrity of the panel. The value shows duration of the period(in minutes), during which the surface of the panel not facing the fire maintains a temperature that meets the safety criteria.

Other technical characteristics of sandwich panels are as follows:

- declared operational period - 30 years or more;

— resistance of the cladding to corrosion and fungal infections;

- environmentally friendly material;

Fiber cement facade panels

Fiber cement panels are made from cement with the addition of mineral fillers and cellulose fibers, which make up 10% of the total volume. This finishing material is used for cladding both new and old houses. The panels are mounted on a wooden or metal sheathing fixed to the wall, and they are usually fastened to each other using tongue-and-groove locks.

The panels can have various reliefs that imitate natural materials - stone, wood or brickwork. An acrylic or polyurethane coating is applied to the surface of the slabs, and sometimes a layer of stone chips is also used in addition to it. The panels are produced in different thicknesses, which range from 8 to 15 mm. The mass of a slab with a thickness of 8 mm is 16 kg/m², and a slab with a thickness of 15 mm is about 30 kg/m².

Positive traits of this material are as follows:

— service life of the cladding is at least 20 years;

— high frost resistance of the material;

— inertness of slabs to corrosion and biological damage;

- resistance to ultraviolet radiation, since the composition of the coloring compositions includes substances that absorb Sun rays;

- absolute non-flammability of the material;

— resistance to temperature changes;

— environmental friendliness of the cladding;

- sound absorption - about 29 dB.

The disadvantages include the following:

— some models of slabs require additional finishing with acrylic paint after installation;

— the hygroscopicity of the material is 7%, which can lead to deformation processes;

- not very high impact resistance of the panels - about 0.25 kg/cm².

Video: example of using special cement panels for finishing a facade

Finishing the facade with clapboard and siding

Lining for finishing facades is made from different materials and can have different shapes, as well as names. Thus, such cladding is made from traditional wood, polyvinyl chloride (PVC) and metal.

Wooden facade lining

This type of material is a well-processed board that has a groove and a tenon along its entire length on different sides, which work like a lock when installing the lining on the wall.

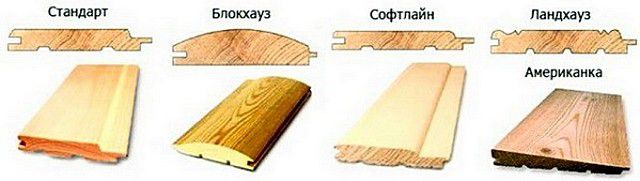

Wooden facade lining is made in different forms, therefore, when choosing it, you need to immediately decide what effect you would like to get after installation is completed.

Lining is made from different types of wood - it can be oak, larch, ash, pine, spruce, aspen, linden and other materials. The price of finishing directly depends on what wood it is made from. In addition, the cost also depends on the class of finishing material, of which there are four, and each of them has its own quality parameters:

— Extra class is a high-quality lining with a perfectly flat and smooth surface that does not have any flaws.

— Class “A” lining is also of high quality, but its lamellas may have minor irregularities and the presence of one knot per 1500 mm of length.

— Class “B” is a material of average quality, which may have more flaws, such as dark spots, as well as up to four knots for every 1500 mm.

— Class “C” is a low-grade lining, which allows a large number of knots with a diameter of up to 25 mm, as well as dark spots and blind cracks.

When choosing lining, you must remember that this classification applies to all types of wood from which the finishing material is made.

Siding

In essence, it is the same lining, but unlike it, it is fixed to the surface of the walls with an overlap and does not have tongue-and-groove joints. This material is made of wood, vinyl and metal, and may have polymer coating various colors, as well as imitate the textured pattern of wood or stone.

It should be noted that the shape and method of fastening this material even more reliably protects the wall than traditional lining. This feature is ensured by the fact that each of the lamellas in the upper part, along its entire length, has a slope along which moisture falling on the surface has the opportunity to flow down the cladding without getting on the main wall or the insulation attached to it.

Produced in the form of single or double lamellas. In addition, for finishing the facade, especially its basement part, panels are used that have various reliefs that imitate smaller tiles or brickwork. Distinctive feature siding panels is also an overlapping method of fastening, that is, the upper mounted row is superimposed on the mating locking part of the lower one.

If you plan to install this cladding on concrete or brick wall, as well as on top of the insulating material, then to secure it it is necessary to equip the wall with wooden or metal sheathing. If you need to sheathe a flat wooden wall, then the slats or slabs are fixed to it using self-tapping screws.

Since wooden lining can also take the form of siding, the table below shows comparative characteristics cladding made of vinyl, metal and wood:

| Index | Vinyl (acrylic) siding | Metal (steel) siding | Wood siding |

|---|---|---|---|

| Raw materials for the manufacture of cladding | Polyvinyl chloride (PVC) | Galvanized steel with polyurethane coating | Natural wood of various species |

| Temperature for installation work | From 0 to +35 degrees - this is explained by the ability of the material to expand at elevated temperatures and become brittle at low temperatures. | Not limited | Not limited, but before installation it is recommended to adapt the wood to the temperature environment. |

| Operating temperatures during operation | From -50 to +50 degrees | From -50 to +80 degrees | From -80 to +80 degrees |

| Ignition temperature | Non-flammable, melting point + 450 degrees | Non-flammable when exposed to high temperatures deformation of the material occurs | + 300 degrees. For comparison, the burning temperature of a match: + 600 degrees |

| Fire safety | Does not support combustion | Does not support combustion | Highly flammable material |

| Hygroscopicity | Non-hygroscopic | Non-hygroscopic | High, so special wood treatment is required |

| Sensitivity to temperature changes | Medium - panels can "play" due to linear expansion. | Low | Average |

| Surface treatment (optional) | Not required | Not required | Impregnation with antiseptics and fire retardants is required. |

| Coloring | Not required | Not required | Requires paint, stain or varnish. |

| Color range | About 20 pastel monochromatic colors, as well as imitation of the texture of natural materials | More than a hundred colors and imitation of textured patterns, as well as several types of decorative coatings | The color range is limited by the colors of wood; it can be expanded by using coloring compounds. |

| Color restoration | Impossible | It is possible by using special coloring compounds, but their price is quite high | Perhaps using special coatings. |

| Types of surface textures | Smooth, embossed, imitating brickwork, natural wood, chipped stone. | Smooth, embossed and embossed. | Smooth |

| Use of panels and slats of different sizes | Not possible for the main finishing material, but possible for fittings. | Maybe | |

| Installation | Lightweight, thanks to special mounting areas on the panels designed for fastening elements. | Easy to install and secure. | A more complex process when installing horizontal slats. |

| Resistance to mechanical stress | High at normal and low at negative temperatures, as the material becomes brittle. | Low, deformation (dents) is possible after even minor impacts. | High |

| Scratch resistance | High. Such damage is invisible, since the material is colored in the mass. | Average. If a scratch is made, corrosion can damage the metal over time. | High |

| Sound and thermal insulation | Average | Low | High |

| Cladding care | Needs cleaning | Does not require complex cleaning, just wash it with water. | Requires periodic maintenance - cleaning and replacement of the protective paint coating. |

| Weight | 1.8÷2.25 kg/m² | 3.9÷5.8 kg/m² | Depends on the species and quality of the wood. |

| Cladding thickness | 0.7 – 1.2 mm | 0.48 – 0.61 mm | 20 – 40 mm |

| Maximum lamella length | up to 3,660 mm | up to 6,000 mm | up to 6,000 mm |

| Environmental friendliness | The quality is confirmed by certificates. | Natural material that creates a favorable microclimate. | |

| Low | Low | High | |

| Service life guaranteed by the manufacturer | Up to 50 years with proper installation. | Up to 50 years with proper care. |

Another option is a block house, which is made from the same materials as traditional cladding, but differs in its shape, imitating a semicircular cut of a log. Thus, a house covered with this type of material looks like log house. All characteristics siding presented in the table also correspond to the qualities of a block house made of vinyl, metal or wood.

Based on all the data on various façade finishes presented in the publication, it will be possible to draw a conclusion about which one is most suitable for a particular building built from a particular material. Probably, at the same time it makes sense to evaluate not only the quality and decorative features of the cladding, but also the possibility of carrying out self-installation, since inviting masters always costs a considerable amount.

October 5, 2016Specialization: facade finishing, interior decoration, construction of cottages, garages. Experience of an amateur gardener and gardener. We also have experience in repairing cars and motorcycles. Hobbies: playing the guitar and many other things that I don’t have time for :)

Finishing the facade of any building performs several important functions, including shaping the design of the building, its thermal insulation and even protecting walls from negative impacts environment. Currently, there is a huge range of finishing materials, which, on the one hand, simplifies the finishing, and on the other hand, complicates the choice. To help you with this issue, below I will talk about several modern versions finishing, their features and technologies.

General information

Conditionally everything existing options decoration of the facade of a private house can be divided into several types:

- wet (plaster) – involves the use of all kinds of plaster solutions, which are applied to the walls in liquid form;

- dry - carried out using hanging frames and all kinds of panels that are mounted without the use of liquid solutions;

- cladding - in this case, the walls of the facade are covered with finishing materials, for example, tiles, stone, etc.;

- Brick cladding – consists of erecting facing masonry around the perimeter of the house.

Wet finish

If you are interested in the most cheap finishing, then stucco is an excellent choice as it provides an attractive appearance to the home and is inexpensive. True, for the sake of objectivity it is necessary to mention some of its shortcomings:

- wet finishing is less durable than dry;

- finishing can be done only in the warm season;

- finishing takes longer, while the process itself is more labor-intensive;

- the surface turns out to be less durable than when finishing using a dry method, especially when it comes to technology in which the façade is plastered over insulation.

Keep in mind that plastering work There are several types:

Rough plastering

Rough plaster is performed for the purpose of leveling walls for subsequent finishing, for example, for painting or finishing with decorative plaster. Can be used as a plaster composition cement mortar. However, if you want the coating to be truly high-quality and durable, it is better to use special plaster mixtures.

The cost of such mixtures depends on the manufacturer, but in general it is quite affordable:

Below we will briefly consider how to decorate the facade of a house with plaster yourself:

- work begins with preparing the facade - removing the old coating, cleaning it from dirt, etc.;

- then the surface of the walls is covered with two layers of primer;

- After this, a reinforcing mesh is attached to the walls. The canvases should overlap about 10 cm. However, if the thickness of the plaster does not exceed 10-15 mm, the mesh can not be used;

- if the plaster will be laid down in a thick layer, it is necessary to attach beacons to the walls, which will provide flat surface walls For this purpose, special profiles are used, which are glued with cement mortar.

The beacons must be positioned so that they are all in the same vertical plane. To do this, you should use a building level; in addition, you can stretch the threads between the outer beacons on the wall to align the intermediate guides;

- then, using special equipment or manually with a ladle, as shown in the photo above, a liquid layer of plaster (spray) about 5-7 mm thick is applied to the wall;

- after the first layer has dried, a second layer with a thickness of no more than 15-20 mm is applied. In the process of casting it, the composition is immediately leveled by the rule along the beacons;

- After completely leveling the walls, you need to wait for the mortar to set, and then you need to rub it in with a special trowel. In this case, you need to remove the beacons and fill the cracks with plaster solution.

To align the outer corners, special plaster perforated corners should be glued to them.

After the plaster has hardened, it is necessary, after which you can begin the subsequent finishing.

Decorative plastering “fur coat”

Quite popular is the exterior wall decoration, which is called “fur coat”. It consists of a special application of ordinary plaster mortar to the walls.

To perform such finishing, you need special equipment that supplies the solution under pressure and sprays it. The result is an original texture that resembles a fur coat. Hence its name.

It must be said that “fur coat” is the most budget-friendly finish. At the same time, you can paint the facade and get a completely presentable appearance of the house.

If you do not have special equipment, you can apply the fur coat using a broom and stick. In this case, the broom needs to be dipped into the solution and hit with its base on a stick towards the wall. As a result, splashes will fly onto the wall, providing the necessary texture.

As for the technology of applying plaster, it is extremely simple. Moreover, in this way it is possible to finish both the facade of a plastered house and an unplastered one, if, of course, the walls have minor irregularities. The main thing is to ensure that the composition spreads evenly.

Applying decorative plaster over insulation

I’ll say right away that decorative plaster can be applied directly on top of the rough coating, however, as an example, let’s consider the most difficult option– plastering over insulation. This finishing technology is called “wet facade”.

To complete this work you will need the following materials:

- facade insulation - most often mineral mats or expanded polystyrene are used for these purposes;

- glue for installing insulation;

- umbrella dowels;

- fiberglass mesh;

- facade decorative plaster - the cost depends on the type of mixture composition. On average, the price starts from 340 rubles per bag;

- paint for exterior finishing.

When purchasing, make sure that the brand of insulation is suitable for finishing using the “wet facade” technology. This information is usually contained on the packaging.

The finishing process itself is as follows:

- as in the previous case, work begins with preparing the facade and priming it;

- then the facade is covered with insulation. The slabs must be located in the same plane and the seams must be bandaged, i.e. according to principle brickwork. To ensure that the insulation can be aligned with the wall, the adhesive should be applied in lumps.

At this stage, the window slopes are also covered with insulation;

- then the insulation is additionally fixed to the wall with dowels. The latter should be located as shown in the diagram above. The dowel caps must be recessed, otherwise they will interfere with further finishing;

- after this, the existing gaps in the thermal insulation must be filled with scraps of insulation or special foam. In addition, convex areas should be rubbed with a special grater so that the resulting walls are completely smooth;

- after this, the screw heads should be filled with glue and also glued metal corners for all external corners. Thus, preparation for reinforcement is carried out;

- Next, the fiberglass mesh is glued. To do this, adhesive several millimeters thick is applied to the surface of the insulation, after which a mesh is applied to it and embedded in the solution with a spatula. Keep in mind that the mesh should overlap and turn over at the corners.

After the surface has dried, the glue is reapplied in a thin layer. Wherein you need to try to level the surface of the walls as carefully as possible. This procedure resembles puttying;

- After the glue has dried, two layers of primer are applied to the surface using a paint roller. Try to prime the walls with an even, thin layer to avoid drips;

- Next, decorative plaster is applied. It is best to perform this procedure with a wide spoon. It must be leveled on the walls so that the thickness of the layer is almost equal to the grain of the filler;

- after the composition has set, the surface must be rubbed using the same grinder, making reciprocating or circular movements;

- At the end of the work, the facade is painted. The paint is applied in two layers with a paint roller. Hard to reach places can be tinted with a brush.

Apply decorative plaster necessary in one go, otherwise border joints will be noticeable on the surface.

This is the installation process wet facade completed.

Wall-mounted finishing

Finishing nuances

Curtain façade or otherwise dry finishing in Lately is becoming increasingly popular. This is due to the durability and practicality of such a solution.

In addition, facade materials for such finishing are available in a wide range, which allows you to give the building any design.

Before getting acquainted with these materials, let us briefly consider the features of this technology. It consists of installing the frame on the walls, which allows you to place insulation and vapor barrier between the sheathing and the wall. Of course, insulation is an optional procedure and is performed at will.

- The frame installation process looks like this:

- work begins with preparing the facade - unnecessary elements are dismantled, crumbling and falling off old plaster is removed;

- if the facade will be insulated, before installing the frame you need to attach a vapor barrier mesh to the walls; Next, vertical racks are installed, which can be used as wooden beams or metal profiles

, which are used for installing drywall. To fix the racks on the wall, you can use adjustable brackets, which in turn are attached to the wall with self-tapping screws or dowel nails.

- The principle of installing racks is reminiscent of installing guides for plaster, since they all must be located in the same vertical plane. In this case, the distance from the wall to the rack should be slightly greater than the thickness of the insulation, and the distance between the racks should be equal to the width of the insulation;

- then insulation is placed in the space between the studs. On top of it, another layer of vapor barrier is attached to the frame; at the end of the work, counter battens are attached to the frame, to which the façade panels are subsequently fixed Decoration Materials

for walls. The location of the counter-lattice depends on the type of finishing material and the location of its mounting holes.

This completes the installation of the frame.

We have become familiar with the main points of installing the frame, now I will tell you what materials can be used to cover the frame.

So, most often for these purposes they use:

- wood finishing materials - such materials include lining, block house, imitation timber and logs. In addition, recently it has become fashionable to sheathe walls with plank. Essentially, this is the same lining, but with beveled ends.

Most often, wood materials are used for private wooden houses, since they are environmentally friendly and allow you to preserve their natural attractive appearance. The cost of wood materials starts from 300-350 rubles per square meter;

- plastic (vinyl) siding - consists of panels that resemble in texture wooden boards. This material is a good alternative to wood, as it does not require maintenance, and plastic is cheaper - from 200 rubles per square meter;

- metal siding is another alternative to wood siding. Externally, the panels reliably imitate the texture of wood, which is applied to the surface using a photographic method.

The disadvantage of this material is its high cost, noise during wind and precipitation, as well as high thermal conductivity. In addition, the cost of the material is quite high, ranging from 400-500 rubles per square meter. Therefore, metal siding is most often used for finishing non-residential buildings;

- plastic facade finishing slabs - according to performance qualities They resemble vinyl siding, since plastic is used as a base, however, they differ in appearance. Their surface imitates natural stone, tiles, brickwork, etc.;

- basement siding– externally it can imitate a variety of finishing materials, from plaster to natural stone. This material is more durable and wear-resistant than wall siding. It is often made from reinforced cement.

- façade cassettes are square panels made of galvanized steel, aluminum or composite alloys. Typically, this material is not used for finishing residential buildings, so it is more suitable for offices and shopping centers.

These are, perhaps, all the most common materials for finishing the facades of houses using the dry method. All of them, as a rule, are attached to the frame using self-tapping screws, so their installation does not cause any difficulties. The only thing is that some panels require preliminary installation of a starting profile, which should be located strictly horizontally along the perimeter of the building.

Facing

Considering different kinds finishing, it is impossible not to mention wall cladding with materials such as:

- thermal panels;

- clinker tiles;

- a natural stone;

- brick.

Thermal panels

Thermal panels are facade slabs that consist of two layers:

- bases - is an insulation made of polyurethane foam, polystyrene foam or extruded polystyrene foam;

- decorative covering- it could be marble chips, clinker tiles or other material that performs a decorative function and protects the insulation from environmental influences.

Thus, Thermal panels allow not only to veneer, but also to insulate walls. Their installation does not require a frame, since they are fixed using dowels.

The cost of thermal panels depends on the manufacturers and materials from which they are made, but in general these cannot be called budget:

If you are thinking about how to decorate a facade for decades, then it is best to give preference to clinker tiles. Some manufacturers guarantee it for 100 years or even more.

The fact is that this material is really durable and at the same time not afraid of atmospheric influences. Externally, the tile resembles a brick, so a wall finished with it cannot be distinguished from brickwork. Moreover, there is a large selection of its colors and shades on sale.

The clinker is glued to the walls like regular tiles using special glue. True, this process cannot be called simple, since the tiles must be evenly positioned and the seams must be uniform. In addition, grouting joints is a rather complicated procedure, so it is better to entrust tiling to specialists.

The cost of clinker tiles starts on average from 1000 rubles per square meter. The cost of tiles from European manufacturers can reach several thousand rubles per square meter.

A natural stone

Natural stone on facades always looks fashionable and attractive. In addition, this material is practically eternal. True, along with its advantages, it also has some disadvantages:

- has a lot of weight, as a result of which it places a large load on the foundation;

- the cost is quite high compared to other materials - the price of processed stone starts from 800-1000 rubles per square meter. True, in order to reduce the cost of finishing, natural stone can be replaced with its artificial counterpart, made of plastic concrete.

Therefore, stone is most often used to decorate not the entire facade, but only its individual elements, such as the base, corners of the building, etc.

The stone goes well with other finishing materials - brick, clinker tiles, plaster, etc. In addition, the facade using it can be decorated with additional decorative elements. For example, façade mosaic looks very beautiful.

Brick

Brick has been one of the most popular facing materials for many years. This is due to its attractive appearance, strength and durability. In addition, it reliably protects the facade walls from negative influences.

But, like other materials, brick has its disadvantages:

- heavy weight - therefore, before finishing the facade, it is necessary to make a foundation, unless the foundation of the house was originally designed for such cladding;

- high cost - starts from 10-15 rubles per brick;

- enough complex installation– facing masonry must be done by a high-class mason.

The construction of facing masonry resembles the construction of an ordinary “half-brick” wall. The only thing is that every three rows must be connected with flexible ties. In addition, vents should be made at the top and bottom of the wall to ventilate the space between the walls.

Here, in fact, is all the information about how and how to beautifully decorate the facade of a house.

Conclusion

Finishing the facade of a house can be done using different technologies and using a variety of finishing materials. To do right choice, you should decide on the design of the facade, the budget you plan to spend on finishing, as well as the tasks of finishing - this could simply be decorating the facade or insulating the walls.

If you have any questions regarding the finishing of the facade or the choice of materials, ask them in the comments and I will be happy to answer you.

Cladding a private house is an important final stage of construction. And at this stage, most developers choose the cheapest finishing for the facade of the house. Why is this happening?

On the one hand, the cladding of your own home must meet all the standards of reliability and aesthetics, and on the other hand, it is obvious that it is not worth throwing away a large amount of money, without guarantees that such a decision will be fully justified.

Only one family in ten can afford to choose any finishing option, regardless of its high cost. The remaining 9 families, which is 90 percent of developers, are trying to save as much as possible and choose the most cheap way facade finishing, sometimes even to the detriment of functionality and visual beauty.

Going to extremes will also not be the best option. If we stop at the very budget option, then you can lose on the performance characteristics of the facing material. As a result, it will not withstand adverse conditions well natural conditions such as: wind, frost, snow, rain. There is a saying about this: “the miser pays twice.”

Cheap cladding of the facade of a house is quite possible, you just need to choose the most best option, the cheaper it is to finish the facade of a house, which takes into account all the most best characteristics material. In order to competently decorate your home, while saving a lot of money, you should decide on the main aspects of choosing the material. If you purchase a good and reliable finishing material, then this is already 50% success.

Selection of facing material

When choosing, you need to know that they mainly pay attention to aesthetic characteristics. There is no doubt that the “beauty” of such cladding is a very subjective question, because it depends on the individual preferences of each owner.

Nevertheless, there are parameters of facing materials that will not go unnoticed in any case. You can choose the most cheap material for the facade, you just need to take a closer look at criteria such as:

- availability of color lines provided by the manufacturer of the façade material;

- parameters of resistance to fading and external defects;

- what raw materials the finishing material is made from, including its environmental friendliness.

Another important criterion is the durability of the facade. When choosing an inexpensive material, you need to make sure it is durable so that it does not have to be replaced every year. Because cheap cladding of the facade of a house, initially low-cost, can result in annual renovations or repairs, which will hurt the budget of the thrifty owner.

Total cost of installation of facade materials

How to get a brick cheaply? Buy a good brick with minor defects. This can be done at the factory or you can buy leftovers from the dealer's warehouse.

By choosing this inexpensive facing material, you don’t have to worry that the facade of the house will fade. The only downside is that there is a chance of efflorescence.

Ceramic tile

The prices for the material are quite low, and the tile itself is a reliable material, so facing the house with ceramic bricks will fully justify the investment cash. Tiles are usually installed over a long period of time, but if there is necessary information on installation facing bricks Work can be completed in a range of 5 to 8 weeks.

Facade tinted primer

Facade primer is a material that has become very popular in finishing facades in shortest time. If the facade of the house is pre-plastered, then it is best to use a deep penetration primer for cladding private housing. For, which is impregnated with an antiseptic to avoid the appearance of harmful bugs.

As you know, the appearance of a house should create a feeling of comfort and coziness. Therefore, you should not save too much, as this may adversely affect the integrity of the house in the future.

Thermal panels

Another economical option is thermal panels. A façade made of this material has many advantages, since dense polystyrene foam is used in its manufacture, which contributes to excellent thermal insulation. IN summer time the house will be cool, and in winter the heat will not escape from the house.

Installation of thermal panels is carried out using ordinary self-tapping screws, so almost everyone can carry out the installation themselves in the shortest possible time.

Another worthy advantage is that the panels can be installed at any time of the year, since the material has increased strength.

A natural stone

Facing the façade with natural stone cannot be considered an economical option at all. However, where it is possible to obtain this facade material virtually free of charge, this will be the cheapest way to finish the facade.

Where can I get natural stone for almost free? Drive to the nearest quarry with your own trailer, or try to buy a stone with minor defects from a dealer.

You can also purchase the remains of stone after facing large houses. If your house is small, then the remains from the cladding big house you have enough to do.

A house made with this particular material will look very beautiful. The stone will give it a very original and unique aesthetic look. The technology of facing a house with stone is very simple.

First you need to prepare the base. This stage includes leveling the surface of the base using ordinary plaster. Then you need to install extruded polystyrene foam on its surface. It is attached using self-tapping screws or dowels. Next, you need to apply an acrylic primer to the surface of the slabs. Are running out preparatory work the fact that a steel mesh is installed on the wall.

Then you need to decide on the mosaic that will be made of stone. You can draw a plan in advance so as not to make mistakes during the work process. You should try very hard, since the appearance of the facade depends on this. Next, you need to rub the seams and joints with mortar. After completing the work, experts advise applying a special varnish to the stone to make the color of the material brighter and more saturated.

Also, in this way you can protect the walls from wind, rain and frost. Facing the facade with natural stone will be the most reliable and, at the same time,...

Conclusion. The cheapest finishing of the facade of a house is possible if you have chosen the cheapest material for the facade or the material whose installation can save money.

Also, if you have the opportunity to get expensive cladding material very cheaply, it will give you the opportunity to make an expensive house façade for cheap.

See if you have the opportunity to remove substandard natural stone or decorative brick with defects. For these materials minor defects are not critical, but such a facade will be installed for centuries, and will look very impressive.

-

So, you choose the materials that can be used to cover the facade of the house. Which material is better? Photos of different facades with different materials used will help you solve this... -

The saying “You meet people by their clothes” applies not only to people, but also to their homes. Therefore, the facade of the house plays an important role for its owners, since...

Most usual option lintels - those that are made of reinforced aerated concrete. This is the most common way. Ready-made lintels for aerated concrete blocks are an independent load-bearing part...

Some Construction Materials, from which walls are erected, immediately imply the need for exterior decoration of the house: the resulting picture is very unsightly. Others may lose their appeal over time. And the third case is extensive crack formation, which is “treated”, but the results remain visible. In all these cases, the question arises: “How to sheathe the outside of the house.” Moreover, most often it is necessary to “sheathe” - without using mortar or other similar means that require large quantity money and time. I want to do everything quickly and, very preferably, inexpensively, and, if possible, with my own hands. Oddly enough, there is a choice of materials and technologies, and a considerable one.

Basic Rules

When selecting materials for cladding a house from the street, be sure to remember that in order to maintain normal humidity in the rooms, the vapor permeability of the materials must decrease from inside the room to the outside. That is, the exterior finishing should conduct steam better than the wall material. Then the increased humidity, which is typical for our homes, will be removed through the walls naturally (explanations in the photo).

If this principle is violated, moisture will accumulate at the interface of materials with different vapor permeability. It condenses, creating conditions for rotting and the development of fungi and mold. IN winter time freezes, destroying the wall material and/or finishing. Sooner or later such a system will have to be dismantled and rebuilt.

The trouble is that only wood meets this requirement. Most other materials for exterior decoration of a house have low vapor permeability. The problem is solved in two ways:

Today the second option is becoming increasingly popular. Very effective thermal insulation materials, allowing you to significantly reduce heating costs. But they have very low vapor permeability (expanded polystyrene and extruded polystyrene foam). When using them, only the second humidity control scheme is possible. When choosing what to cover your house with, consider these points.

Wood paneling

Wood has been used in construction and decoration for centuries, and it seems that it will be relevant for a long time. All thanks to its excellent appearance and ability to regulate indoor humidity. This is perhaps the only material that will remove excess moisture without problems, regardless of what material the walls are made of.

Wooden cladding can have a completely non-standard appearance: different colors and sizes, different direction. It's simple, but the effect is amazing

The most popular materials for wall cladding are block house and imitation timber. There is also lining for exterior finishing - it is thicker than what is intended for it, but otherwise it is no different.

The block house imitates the surface of a rounded log - the front part has a rounded shape. Imitation timber is very similar to planed timber. Both types of cladding are attached to the sheathing, then sanded and coated with protective impregnations, and optionally varnished or painted.

What does lumber look like for exterior cladding of a house?

If you can't decide how to cover the outside of a foam block house, consider wood cladding. In this case, lathing (metal or wood) is nailed to the walls. If necessary, insulation is placed between the slats - basalt wool(foam or polystyrene foam cannot be used) and then the wood sheathing is nailed on.

This building is sheathed with imitation timber. Under the skin there can be brick, log frame, frame or any of the building blocks

If you need the most cheap option, for most regions of Russia this is an ordinary planed board. Its thickness is from 40 mm, it is stuffed in the same way as a lining or block house onto the sheathing, the lower end of the upper board extends 10-20 mm onto the one located underneath it. It turns out the principle of the cone. So you can veneer it cheaply country house or even residential. When properly processed, such cladding has a very good appearance.

How to cheaply cover the outside of a house? For middle zone Russia - wooden planed board

The disadvantages of such finishing are the same as with any wood: it can be damaged by pests, rot, without proper care it quickly loses its decorative effect, becomes dark and ugly. If you want to cover your house and not think about it for years, this is not your choice. Behind wood paneling maintenance is required, and, most often, annually.

Siding

In some regions, planks and other lumber are not the most affordable materials. In this case, it’s cheaper. This is the option when, having completed the finishing once, you can forget about it for a long time.

If you are thinking about how to decorate the outside of a timber house, perhaps your option is siding

Since the sheathing is nailed onto the sheathing, the façade is ventilated. If you need to inexpensively finish wooden walls(made of timber, logs, panels) siding is one of the options. It can also be used for buildings made of any other material: foam block, aerated concrete, slag-filled concrete, etc. This cladding is universal.

Vinyl

Siding is made from polyvinyl chloride (PVC) and is therefore also called vinyl. It consists of strips of material 205 and 255 mm wide, 1.1 mm and 1.2 mm thick. The longitudinal edges have a lock on one side and perforation for fasteners on the other (self-tapping screws are more often used).

The siding is also attached to the sheathing. It is recommended to use a special metal one, but impregnated wooden blocks are quite suitable. Only standard starting and side stripes will be required. The only caveat: the screws need to be “undertightened” a little, leaving some play in order to compensate for temperature changes in the materials. With this installation, the siding will not crack due to stress.

The advantages of this material for exterior cladding of a house: low prices, easy installation.

Flaw vinyl siding: it fades quickly in the sun, so it is advisable to use soft colors. Has quite a wide temperature regime operation: from +50°C to -35°C, but even in slight frosts it becomes brittle and easily damaged.

One more point: houses covered with siding and having a broken configuration look good. If the building is rectangular, without architectural frills, it does not have the most attractive appearance (as evidenced by the photo below).

If the building is simply long, without reliefs or protrusions, covering the walls with sading will not embellish it very much

Metal

Metal siding consists of strips of thin aluminum or galvanized steel, onto which a protective and decorative coating is applied. It has the same fastening system as vinyl.

House cladding metal siding simple: you can do it yourself even without much construction experience

The coating can be made of polymers. It is distinguished by its reliability, resistance to burnout and other climatic factors. Its disadvantage is the limited choice of colors. The second coating option is powder coating. The color range is much wider, the paint lasts for years without signs of peeling.

If you are looking for something to clad the outside of your home for a durable and vibrant finish, one of the metal siding options may be right for you. It can be bent, it is very difficult to break, installation is not very difficult: you need good metal scissors, self-tapping screws, a screwdriver or a screwdriver. All installation features are the same as for vinyl, with the only difference being that metal can be installed at sub-zero temperatures.

It is not easy to harmoniously decorate a building covered with metal siding

From the point of view of durability, this is a good option, but from the point of view of aesthetics, it is difficult to work with: it looks too “manufactured”. The building no longer resembles a residential building, but rather a warehouse or some kind of workshop.

Tsokolny

This is one of the varieties of vinyl siding, but it has a completely different configuration, appearance and greater panel thickness. It was developed specifically for decorating and protecting the plinths of buildings, but I liked it so much that it began to be used for cladding facades. External design - brickwork of different types and colors, with or without drawings, wild stone. Sometimes the imitation is so successful that you can understand that it is not brick cladding, but vinyl, only by touching the wall.

It is mounted, like other types, on the sheathing, there are perforations and locks. The difference is that the basement siding panel does not look like a long rectangle, but a certain section of the wall with curly edges. These curly edges are used to join. Accordingly, the sheathing must be adjusted to the size of the fragment. When installing, first the edge of the panel is inserted into the already installed lock, a match is achieved, and then secured. The main thing is that during installation, do not overtighten the screws, leaving the siding room to move with temperature changes.

The sheathing can be made of treated wooden blocks (with protective impregnation) or from plasterboard profiles (galvanized). How to install basement siding on a basement, watch the video. It is mounted on the wall in the same way. The difference is in area.

Fiber cement boards and siding

Relatively recently, a new cladding appeared on our market: fiber cement boards and siding made of the same material. They consist of wood fiber, quartz, mica, cement, and may contain chlorine and asbestos (some materials used only for exterior finishing). This mixture is formed into sheets, then dehydrated in several stages, and fired using some technologies. Then a protective and decorative coating is applied to the surface:

The coating can be smooth - glossy or matte, or can imitate brickwork, wood and other finishing materials. Installed on guides mounting strips, attached to the wall with clamps. This material may suit you if you don’t know what to cover frame house outside: it creates a continuous surface, the panel joints are sealed and precipitation will not get inside.

This house is also lined with fiber cement slabs

Watch the video to see how to attach fiber cement boards.

Fiber cement siding is produced using the same technology, only it is molded into long strips. They are basically standard: 3600*190*12 mm. This material is cut with a jigsaw, installed on a wooden sheathing with an overlap (like a cone) and nailed to it or screwed with self-tapping screws.

Thermal panels

Thermal panels are a material that performs two functions at once - cladding and external insulation of houses. A layer of decorative coating is applied to the thermal insulation layer at the factory. It looks like marble or natural stone, does not burn, and has low water absorption characteristics.

This finishing material is made from foam plastic, mineral wool or extruded polystyrene foam. Depending on the type of insulation, the installation method is selected: polystyrene foam and polystyrene foam are glued to the appropriate composition. The joints are closed with a special aluminum strip or rubbed with paste.

Based on mineral wool, they are mounted only on a special system of profiles; the joints are also sealed.

Very attractive idea- immediately insulate the house and cladding it. Excellent appearance, and the characteristics of this cladding are impressive. It’s just a pity that there is little operating experience and no reviews yet: it appeared only recently.

There are also clinker thermal panels. Clinker tiles are glued to the insulation. The material is not cheap, but the characteristics are impressive, as is the variety of finishes.

Another option for thermal panels is with clinker tiles

The choice of materials that can be used to cover a house at any time - winter or summer - is considerable. There are expensive options, and there are cheaper ones. In any case, in addition to cost, be sure to consider vapor permeability. Then you won’t have to deal with mold and dampness.

- Turkey stewed in a slow cooker: spicy, with vegetables, in sour cream, cream and walnuts

- Types of speech: description, narration and reasoning

- Girls and women almost always associate white shoes with a wedding dress, although the white color of shoes has long been no longer required. A...

- New

- Why you shouldn't cry in front of the mirror

- Martyrs Tatiana. Moscow Church of St. Martyrs Tatiana Temple of the Martyr Tatiana at Moscow State University schedule

- Milotici: return of the Russian village Moravov Alexander Viktorovich

- Making sounds for children Lessons on making sounds for children

- Recommendations: what to grease the pies to make them rosy and appetizing

- Actors Spiderman Aunt May Aunt May in Spiderman

- What does a lizard tattoo mean?

- Deciphering the natal chart of the house

- What does mulberry help with?

- Photo report “Birthday of Samuil Yakovlevich Marshak in the group”

- Breathing at high pressure Breathing correctly at high pressure

- Bryansk State University named after

- Tasks to test spelling and punctuation literacy

- Application...burning, grow...sti, to...sleep, m...roll, warm...up, sk...roll,...

- The Forex Economic Calendar is a reference book for every trader, regardless of trading experience and level of professionalism, and especially...

- Interesting signs about spiders